PATAS

Especially developped for the careful delimbing of larch, pine, spruce, pre-delimbing Douglas fir and eucalyptus, poplars or teak plantations

Simple facts and figures are giving proof of the company’s self-confidentially claimed quantum leap in the field of delimbing higher trees: For the time being, foresters and service providers were glad to finish four trees or maybe six per hour by piecework. Using the PATAS will enable them to do 30 up to 50 trees an hour (in european forests, in plantations it will be 80 – 100 trees an hour). While usually no one would take the effort to continue delimbing much higher than eight meters, the advaligno machine allows for a range between 12 and 15 meters with the easiest possible operation. When you see the machine at work, you immediately understand how this immense advantage in efficiency is achieved: the PATAS will go up the tree for a complete delimbing process in nearly incredible eight to ten seconds – and back down again!

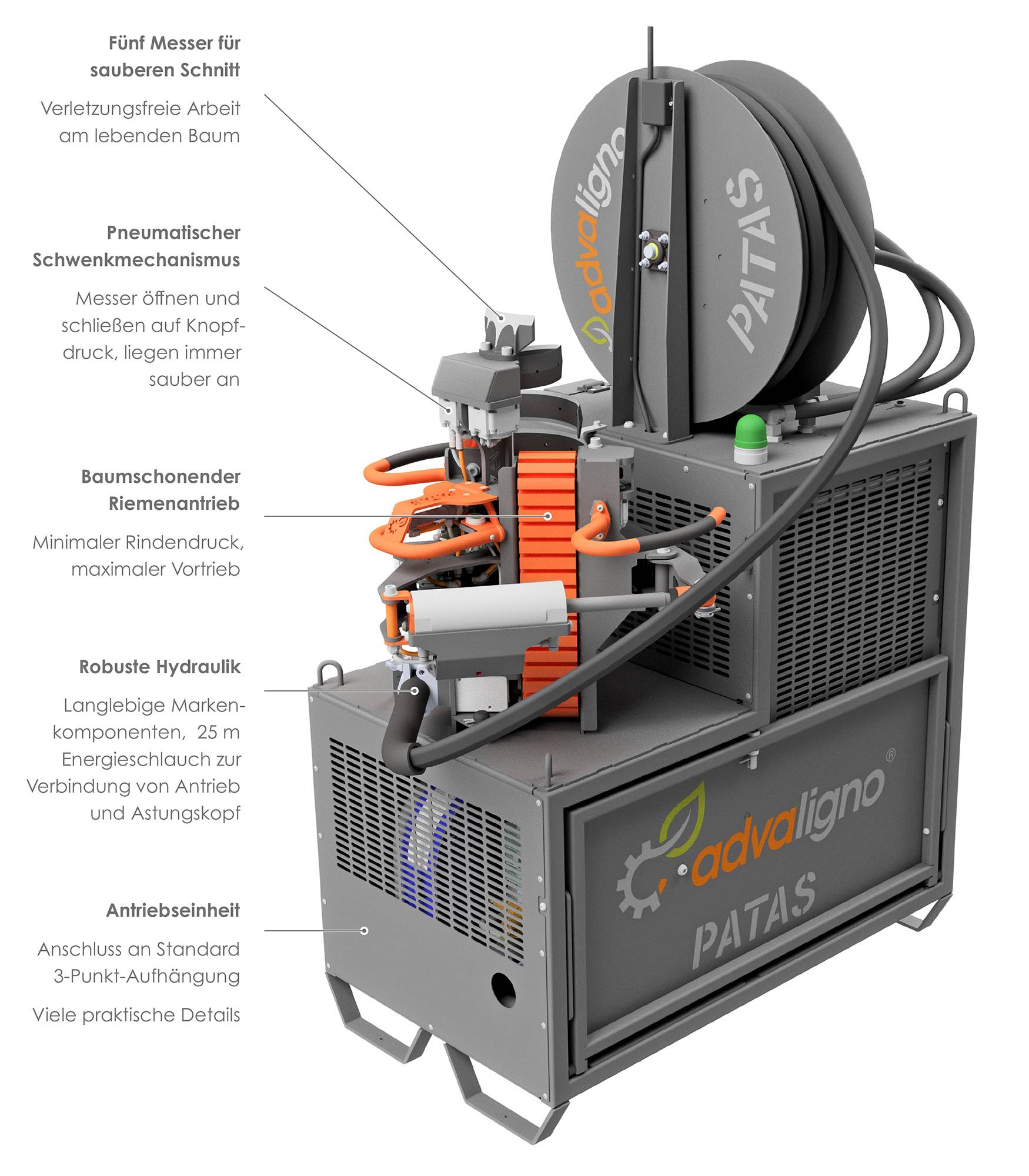

The cutting head reaches the necessary speed via hydraulically driven rubber belts that guarantee minimum bark pressure and maximum grip. During the whole year, precisely designed blades separate all branches cleanly and safely from the tree. The entire system consists of two modules: a drive unit for the connection to standardized small tractors, as well as the already mentioned cutting unit, which then works on the tree. For sure we have secured our technology by patents.

Also usable as a small-sized Harvester

We are encouraged, that forestry experts indicated that our PATAS offers an additional benefit: You may use it as a small-sized harvester. Trees, intended for felling may be delimbed by our PATAS. That prevents you from the time-consuming, dangerous and cost-intensive delimbing after felling the tree. To gain that advantage it is irrelevant, whether you want to fell the tree next week or in 20 years – the lower 12-15 meters keep delimbed. That means, in most cases you can obstain from expense use of a harvester or the manual delimbing after felling – that saves you money and time.

Technical data

Information on the trees

• Trunk diameter 25 to 12 cm - 10“ to 4.5“ (max. DBH at bottom / min. at top)

• Branch strength up to 3.5 cm - 1.4“

• Delimbing height 12 to 15 meters - 40 to 50 feet

• Speed of the cutting head approx. 4 m/s - 13 ft./s

• Duration of delimbing at 12 m - 40 ft. of height approx. 8 seconds

• Possible output 30 to 50 trees per hour (in Europe – about 80 to over 100 in plantations!)

• Clean cut due to special knife technology - no risk of injury to the bark

Special qualities of the cutting head

• Hydraulic drive of the cutting head

• Pneumatically adjustable cutting blade pressure

• Cutting head made of aluminium - weight approx. 50 kg - 110 lb

• 2-person operation

• Downward speed of the cutting head infinitely adjustable

• Infinitely variable acceleration speed of the cutting head to protect the bark of the tree and the drive belts

• Pressure of the counter pressure wheel pneumatically adjustable

• Minimal bark pressure thanks to belt drive

• Pneumatic non-return valve for protection in case of unlikely pressure loss of the pressure wheel

• Drive belts and cutting blades easily replaceable

• Simple and safe handling of the entire system

• Patented

Special qualities of the drive unit

• Drive unit including oil cooler

• 96 litre tank with biodegradable hydraulic oil (PANOLIN HLP SYNTH 32) incl. oil filter and indicator for oil quantity and oil temperature

• Hydraulically driven compressor incl. sufficient air reservoir

• Water separator for pneumatics

• Panel with all important displays such as hydraulic and pneumatic pressure, various control and setting elements, operating hours counter and emergency stop for remote control

• Signal lamp on the drive unit for operating state

• Pneumatic coupling for external air pressure tools

• Robust hose package for hydraulics and pneumatics

• Hose reel for winding and unwinding the hose package

• Components of the complete system from highquality brand manufacturers Handling and ergonomics

Handling and ergonomics

• Electric control via remote control

• Manual control of the cutting head possible via drive unit

• Folding table for easy cranking of the hose reel and transport of the cutting head in the forest

• Stowage feet adapted to lift unit with trucks and stackers - can be used from three sides

• Mount for the cutting head on the drive unit with double lock - safe transport of the entire system

• Four eyelets for lashing and lifting the drive unit with belts

Requirements for the tractor

• Standard three-point suspension for drive unit (Cat. 1 and 2)

• PTO shaft at the drive unit 13/8“, 6 teeth

• Required PTO shaft speed on tractor 540 - 600 min-1

• Required engine power from tractor at least 40 hp

• Required current from tractor 12V

Measures and weights

• Drive unit dimensions incl. PTO guard and three-point suspension (without cutting head): 1,189 mm x 798 mm x 1,900 mm 47“ x 31.5“ x 75“ (width x depth x height)

• Drive unit dimensions incl. PTO protection, threepoint suspension and antenna (with cutting head on mount): 1,333 mm x 865 mm x 1,975 mm 53“ x 32“ x 78“ (width x depth x height)

• Total weight of drive unit incl. hydraulic oil + cutting head approx. 570 kg - 1,250 lb

• Length of hose package between cutting head and drive unit 25 meters - 82 ft.